Wednesday, April 23, 2025

What are some of the most challenging aspects of designing and creating prosthetics?

Prosthetics must withstand daily wear and tear, be lightweight, and still remain affordable. Finding the right balance of materials to meet these requirements can be tricky.

High-quality prosthetics often come with a steep price tag. Making prosthetics more accessible and affordable while maintaining their quality is a critical issue.

Incorporating cutting-edge technologies, like bionics or neural interfaces, can improve functionality but also complicate the design process and increase costs.

These challenges require a multidisciplinary approach, combining engineering, medical expertise, and user feedback to create prosthetics that are both functional and user-friendly

How do you ensure that each prosthetic is customized to fit the individual needs of your patients?

Prosthetics need to integrate well with the user's body to prevent pain or irritation. Achieving a perfect fit can take multiple iterations and fittings. Many users also want prosthetics to look as natural as possible. Combining form and function without compromising either is an ongoing design challenge.

What materials are commonly used in making prosthetics, and how do they impact the functionality and comfort of the prosthetic?

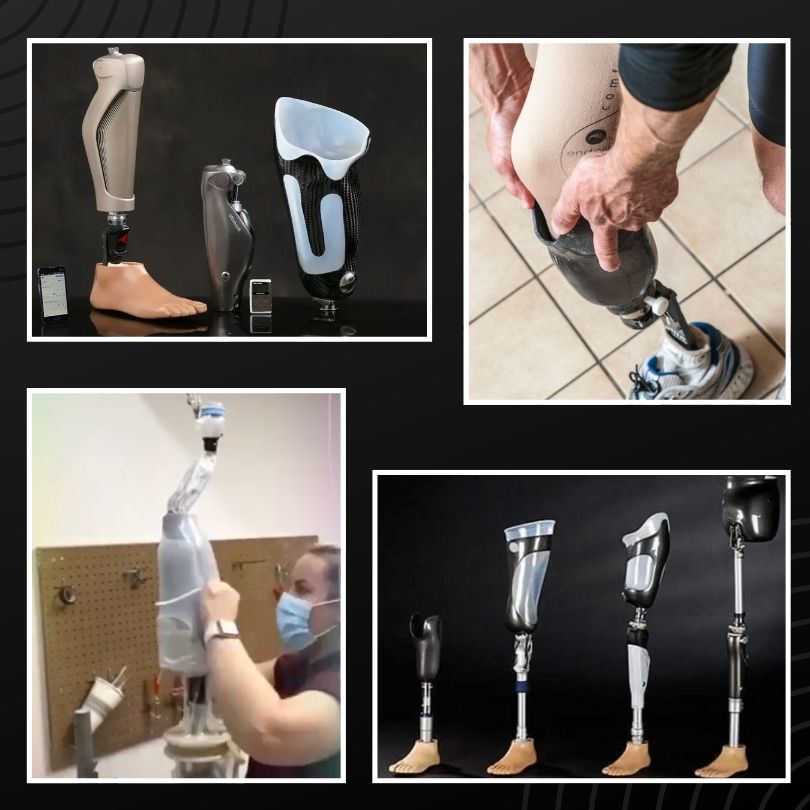

Prosthetics are crafted using a variety of materials, each chosen for its specific properties to enhance functionality and comfort. Common materials include:

Carbon fiber: is known for its strength and lightweight nature. Carbon fiber is often used in prosthetic sockets and structural components. It provides durability and flexibility, mimicking natural biomechanics and reducing user fatigue.

Titanium: This metal is highly durable, corrosion-resistant, and biocompatible, making it ideal for long-term use. Titanium is often used in bone-anchored prosthetics and modular systems, ensuring stability and ease of replacement.

Silicone: Silicone is prized for its softness and flexibility, offering comfort and cushioning for residual limbs. It is commonly used in liners and covers, reducing friction and irritation during wear.

Polypropylene: Lightweight and affordable, polypropylene is used for prosthetic sockets. It is easy to mold and provides decent durability, making it a versatile option.

How long does the prosthetic-making process take?

The timeline varies but can take several weeks to months, depending on fittings, customization, and rehabilitation.

How much do prosthetic limbs cost?

Costs can range from a few thousand dollars to tens of thousands, depending on complexity, materials, and technology. Insurance and financial aid may help cover expenses.

How often does a prosthetic need to be replaced?

Prosthetic limbs typically last 3 to 5 years, but factors like wear and tear, technological advancements, or physical changes can affect longevity.

How do you address and accommodate specific needs, such as different activities (sports, swimming, etc.) or unique anatomical requirements?

Based on the assessment, the prosthetist collaborates with the patient to design the prosthetic limb. They choose the appropriate type of prosthetic—whether it's a basic limb for daily use, a specialized limb for sports, or a high-tech myoelectric prosthetic that can be controlled by muscle signals.

Some prosthetics offer modular designs, allowing users to switch attachments (e.g., a casual foot versus a high-performance foot for running) depending on their activity.

Prosthetics can be tailored for individuals with sensitive skin, nerve pain, or complex residual limb shapes. Silicone liners, custom padding, and advanced suspension systems help ensure comfort and usability.

Once the prosthetic is assembled, the patient undergoes a fitting session. The prosthetist makes any necessary adjustments to ensure the prosthetic fits comfortably and functions correctly. This stage may involve aligning the limb for optimal movement and comfort.

All in all, Prosthetics are not just functional devices; they are life-changing instruments of hope and empowerment, enabling our veterans to embrace lives filled with activity and fulfillment. From the initial assessment to the creation of a fully integrated prosthetic, the process shines as a testament to human ingenuity and deep compassion. With technological advancements paving the way, the future of prosthetics offers boundless opportunities for those who depend on them—giving our wounded heroes the ability to conquer even the highest peaks and redefine their horizons.

To learn more about The Heroes Project and what we do, feel free to explore our website here.🇺🇸